About this deal

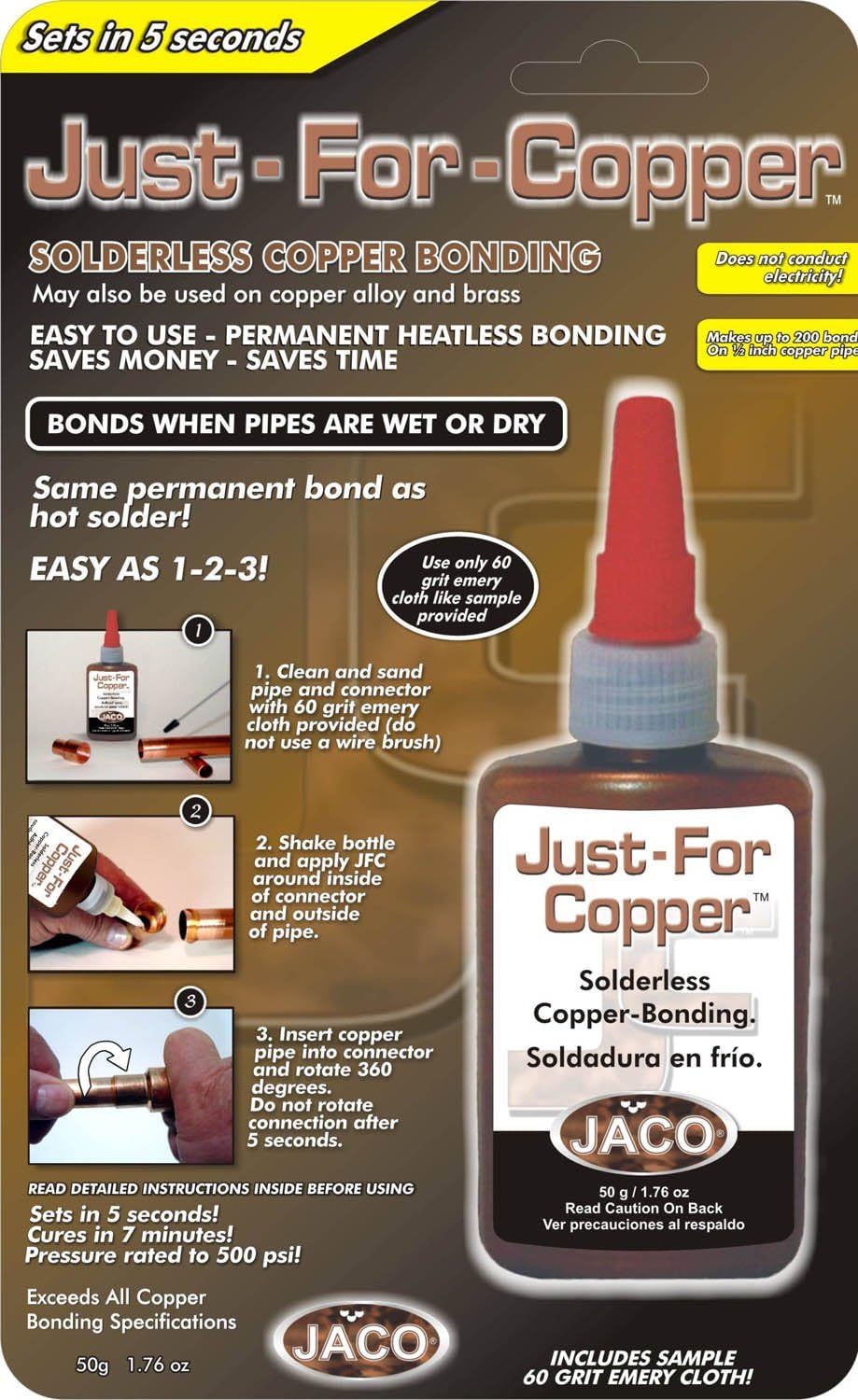

Soldering involves using heat to melt a metal alloy that is then used to join two pieces of metal together. While this method is popular and effective for copper pipes, it requires a bit more skill and knowledge to use properly. Pipe cement is a more common choice for DIYers. Public Health: Properly bonded copper pipes also protect public health by ensuring that hazardous chemicals do not leach into the water supply. Ensuring that the adhesive used meets safety standards is of utmost importance when bonding copper pipes. The curing time varies depending on several factors such as the type of adhesive used, humidity, temperature, and pipe size. Typically, the curing time can range from 30 minutes to several hours. In summary, gluing copper pipes is a necessary skill for any DIY enthusiast or professional plumber to master. To ensure a safe and leak-free plumbing system, it is important to choose the right adhesive, prepare the copper pipes properly, and apply the adhesive correctly. Always prioritize safety precautions, such as wearing protective gear and allocating a well-ventilated workspace. If the joint still leaks after curing, it could be due to incorrect pipe measurements or an improperly positioned fitting. Disassemble the joint and make necessary changes before reassembling and gluing the joint.

So, what should you use instead? Plumbers typically turn to specialized techniques like soldering or brazing to join copper pipes. These methods involve melting a metal alloy (solder or brazing rod) onto the joint, creating a strong and permanent bond that can endure high pressures and temperatures. Expansion of Gorilla Glue and Its Potential Issues To ensure long-lasting and dependable results for your plumbing needs, it is advisable to seek professional assistance. Professionals employ specialized techniques such as soldering or brazing, which involve melting a metal alloy onto the joint. These methods create a strong bond that can endure high pressures and temperature fluctuations, ensuring the longevity of your copper pipes. Temperature Resistance of Gorilla Glue

Applying the Adhesive

Often than not, compression fitting is highly recommended for longer connections, perhaps beyond 10 meters long. This method uses compression or plastic adapters, which then serve as the link between the two pipes. You may also want to clean up the excess adhesive. If you wait until after the adhesive cures, you may need to apply heat to soften the adhesive, which can weaken the bond. Use a scraper tool and a rag to remove the extra adhesive. Assembling the copper pipes and fittings is the most important step of the process. Make sure that you apply the adhesive correctly and attach the pipes and fittings without hesitation. Here are the steps to follow:

To ensure that the adhesive has fully cured before testing the system, use the following guidelines based on the type of adhesive used. Tip: It is essential to use sandpaper with the appropriate grit for the copper pipes you are working with. Consult an expert or visit a hardware store to determine which grit is suitable for your specific copper pipes and fittings. Measure the length of the pipe you need to cut, using a tape measure or ruler. Make sure to account for any bends or corners in the pipe, and add a little extra length for maneuvering. Curing time is an essential part of the copper pipe gluing process, and it must be taken seriously. Always follow the adhesive manufacturer’s recommendations for curing time and conditions to ensure that the joint is strong and leak-proof. Remember to let the joint sit undisturbed during the curing period to prevent premature movement. Leak Testing A notable feature when using shark biting fitting is the fact that you can reuse it up to 4 times. Therefore, if there’s a need for adjustment, you simply take the disconnection tong and retract the connection. Plus, shark biting offers a variety of sizes, making it very popular among DIY users and plumbers. 5. Installing thread adaptersWhen it comes to joining copper pipes, you can’t just rely on any old adhesive. While Gorilla Glue may be a go-to for many DIY projects, it’s not the right choice for copper pipes. Here’s why: It is recommended to use primer before applying the adhesive as it helps the glue create a better bond with the copper pipes. 6. Can I glue copper pipes if they are wet? Next on the list of popular plumbing connections is none other than shark-biting fitting. This has been utilized by both commercial and residential pipe connections. Aside from that, it’s quite renowned in terms of radiant heating systems. Consider how the adhesive will be applied – whether it requires a brush, spray bottle, or application nozzle – to ensure it’s an efficient and user-friendly option for you.

I talked with the plumber yesterday, the plumber who is using the SharkBite fittings for installing tankless units, and to date he has been using the SharkBite fitting onto CPVC coming out of the wall, then using copper for the short plumbing piping to the tankless unit - thus not requiring any bonding or bonding jumpers, but ... he had come in to ask some questions about his next installation and that was indeed a copper piping system - he is now aware that he will need to install a bonding jumper all the way from the first SharkBite fitting to the last SharkBite fitting. Installing the bonding jumper will be easy, he will clamp the bonding jumper to the pipe before and after the first and last SharkBite fittings, bend the copper bonding jumper to follow the copper piping, then install a clamp on EACH section of copper pipe. As he said: "No problem, I'll just have to buy a few more clamps is all." Problem solved. Soldering, discounting lead by assuming the plumbers use lead-free solder, can have hidden issues. Flux, typically far worse a problem on cold water lines, can cause hidden corrosion inside the copper lines. I would think that your adhesive method would be immune to this problem as there is no flux. You can test for leaks by applying pressure to the system and looking for any signs of water or moisture near the joints. 10. What should I do if I notice a leak after the adhesive has cured?Before attempting any repairs or installations involving copper pipes, it is crucial to carefully consider the potential issues associated with using Gorilla Glue. Its expanding nature may not provide a reliable and secure bond capable of withstanding the unique challenges posed by copper pipes. Alternative Methods: To ensure a safe and effective glueing process, it is important to have an appropriate workspace set up. When working with adhesive, it can be messy and difficult to clean up once it has dried, so it is best to designate a specific area for glueing copper pipes. The type of adhesive that you use depends on the project. Some adhesives offer superior resistance to impact while others are easy to apply and cure. The main types of adhesives include: Step 2: Apply cement to both the pipe and fitting. Use a clean, disposable brush to apply a uniform layer of adhesive around the entire circumference of the pipe and fitting. Make sure to coat the surfaces evenly while being careful not to apply too much cement, as excess cement can cause dripping, mess, and weakening of the joint.

Great Deal

Great Deal